DESCRIPTION OF HOUSING

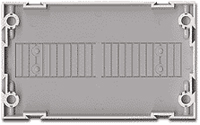

Metal housings in recess-mounted version (OWS - pic.

8), wall-mounted version (ONS - pic. 3) and free-standing version

(OKS - pic. 6, 17) are made of steel sheet, painted with powder

paints (RAL 7035 colour or other, according to customer’s wishes).

Maximal internal width: 4×250 mm

(4 x basic module width) - OWS, ONS, OKS.

Maximal internal height: 8×150 mm

(8 x basic module width) - OWS, ONS.

In case of OKS housing mounted on base, maximal height is

13×height of basic module.

Standard equipment of OWS, ONS and OKS housings includes mounting

channel sections, made of zinc-coated sheet, sheet screws for fixing

of counter boards, mounting sheets and protecting panel brackets.

INTERNAL CONSTRUCTION

Arrangement of channel sections in internal

construction allows for mounting of protecting panel brackets for

counter boards as well as mounting of mounting sheets and TS 35

strips (eurorails).

|

The construction of channel

sections allows, due to appropriate arrangement of holes,

for screwing of brackets in any place, depending on

construction and assembly needs.

Internal construction is fixed to the housings with screws,

which facilitates its removal outside and mounting of

modular equipment.

Dimensions of the basic module are: 250 mm width, 150 mm

height. Our offer includes also protecting panels of

dimensions: width 250 mm, height 225 mm, (with “weakened”

places, which facilitate cutting out of a hole, of proper

size, for electrical equipment). |

ASSEMBLY

Brackets (WP) are fixed to internal

construction channel sections (CMY) with sheet screws (BL).

Protecting panels (P1) are mounted with screws (SP), directly on

brackets, with possibility of sealing with lead. In order to

increase the distance from CMY channel section level, extensions of

brackets are applied and they are screwed directly into the brackets,

without using of any tools.

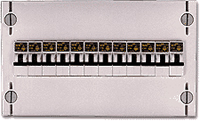

The counter board is mounted directly on CMY channel section, with

sheet screws, which are covered with [ZP] cap, filling the hole.

The offer of H. Sypniewski company includes the counter board

(TL-1F) for monophase counter and the counter board (TL-1F+TLG) for

three-phase counter.

Counter boards are joined without using of tools and additional

fastening elements, because TLG is equipped with special catches,

which join both parts together in a rigid way.

Protecting panel - internal side

Protecting panel with protections

TLG counter board

TL-1F counter board

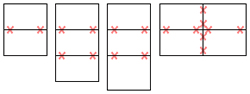

Neighbouring protection panels (P1-1,0 and

P1-1,5), which are mounted at the same depth, can be joined together

with a fastener of protections (so-called "swallow tail "), which

reduces costs of performing of complete housing. Combinations of

joining of individual panels are presented on the figure below:

assembly elements

In case of recess-mounted housings, doors are

mounted on screwed collar. In order to install the housing, the

collar should be unscrewed and then the box should be insert into a

recess. Then the gaps between walls of the housing and the recess

should be filled with polyurethane foam. Then fix the collar with

the door, with four screws.

In case when neighbouring protection panels

(P1) are mounted at different depth, then the hole, which is between

the levels, is covered with side covers.

The construction of side covers [PB] allows for direct access to the

parts being under voltage.

CLOSURE OF HOUSING

Doors are closed in two points – in lower and

upper part. A lock of N-1 type is applied. In case of housings of

greater width double doors are mounted.

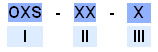

DESIGNATION OF HOUSING TYPE

Designation of housing type contains three blocks:

Block I – construction of housing

ONS – housing for wall-mounting

OWS – housing for recess-mounting

OKS – free-standing housing

Block II – designation of manufacturing number

|

Manufacturing

no. |

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

|

Housing width |

300mm |

550mm |

|

Height |

500 |

650 |

800 |

950 |

1100 |

1250 |

500 |

650 |

800 |

950 |

1100 |

1250 |

1400 |

1550 |

1700 |

1850 |

2000 |

|

Number of

modules on the width |

1 |

2 |

|

Number

ofmodules on the height |

3 |

4 |

5 |

6 |

7 |

8 |

3 |

4 |

5 |

6 |

7 |

8 |

9x |

10x |

11xx |

12xx |

13xx |

|

Number of doors |

1 |

|

Manufacturing

no. |

18 |

19 |

20 |

21 |

22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

Housing width |

800mm |

|

Height |

500 |

650 |

800 |

950 |

1100 |

1250 |

1400 |

1550 |

1700 |

1850 |

2000 |

|

Number of

modules on the width |

3 |

|

Number

ofmodules on the height |

3 |

4 |

5 |

6 |

7 |

8 |

9x |

10x |

11xx |

12xx |

13xx |

|

Number of doors |

2 |

|

Manufacturing

no. |

29 |

30 |

31 |

32 |

33 |

34 |

35 |

36 |

37 |

38 |

39 |

|

Housing width |

1050mm |

|

Height |

500 |

650 |

800 |

950 |

1100 |

1250 |

1400 |

1550 |

1700 |

1850 |

2000 |

|

Number of

modules on the width |

4 |

|

Number

ofmodules on the height |

3 |

4 |

5 |

6 |

7 |

8 |

9x |

10x |

11xx |

12xx |

13xx |

|

Number of doors |

2 |

x – regards only OKS housings

xx – regards only OKS housings (in preparation)

NOTICE: OKS housings are performed at the number of

modules at the height >=5

Block III – determination of housing depth

ONS, OWS housings: O – depth 150mm, L – depth 225 mm

OKS housings: L – depth 225mm

|